Flowers are one of natures most beautiful gifts. Flower Pressing is an age old way to preserve some of that beauty for many years to come!

Made from thick and sturdy pine boards, these will provide plenty of pressure with hand tightening to get the best press!

The photos shown in this blog post is an older version of this flower press - we've changed the wood we make them from to make them more durable and stronger! Please see the product page for photos of the current wood that we use.

Pressing flowers certainly isn't a new idea or process. It's been done for literally centuries. The process is really very much unchanged from the original flower pressing techniques - flatten the flowers and remove their moisture to preserve them. It's something that has been used to preserve flowers for their appearance, and also for historical and botanical purposes.

The pull of the idea is the simplicity of it - anyone can do it with commonly found materials and flowers!

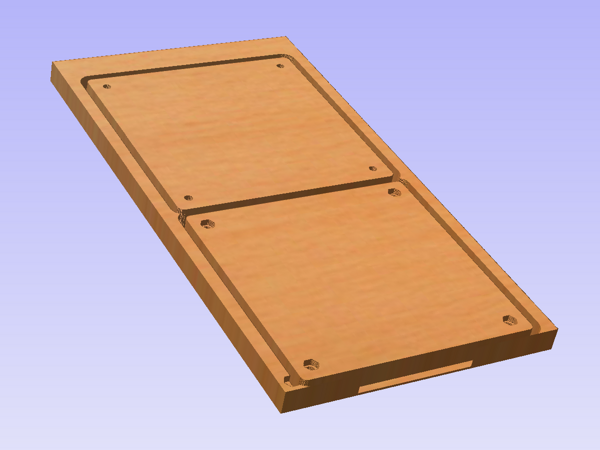

We've designed our flower press out of robust and thick solid pine boards, to allow the boards to remain flat and apply even pressure across the flowers. With simple wing nuts, and an embedded hex head bolt, you can do them up very tightly by hand, without needing any extra tools. The thick boards ensure that the result stays very flat and even.

Coupled with a beautiful design of your choice, and a unique name, it becomes a beautiful and practical item!

We supply the flower press with two pieces of cardboard, which can assist removing the moisture from the flowers. We'd still recommend tissue paper as well, to remove the excess moisture.

These are simple in design, but as with all products - the devil is in the details when it comes to making them!

It all starts on the computer. We developed a design for the two boards, and take into account the size of the bolts, and the size of the hex head bolt on the back. This allows us to make a rebate to tightly hold the hex bolt, and allows you to to tighten up the press without any tools.

Once it's designed, we load it up into our CNC router. This is a computerized machine that can accurately move a spinning router head to shape wood. When I say accurately, I mean that it can repeatably position the router bit within 0.1mm - and generally even better than this! Our machine is fitted with a vacuum table, which means a large vacuum pump is used to temporarily bond the wood to the table. It's a very effective method of holding down wood for CNC machining, and makes loading the machine much faster!

The CNC router then does two passes. For the first pass, we use a 3.175mm end mill bit to do the hex bolt head rebates. We use the smaller router bit for this to ensure we get as tight corners on the rebate as we can. In practice, it still has a small radius in the sharp corners (technically a 1.5875mm radius), but it matches the bolts nicely. It rebates out the hole in one direction, and then reverses direction to clean up any extra marks that may have been left.

Then we move onto the second pass, this time with a 6mm end mill bit. This cuts the holes for the bolts right through the material. Then, it cuts around the outsides of the board. It does this in three passes; going in 6mm deep each time to reduce the strain on the cutter. After cutting, it needs a little bit of hand sanding to finish up the edges and properly prepare the top and bottom. Then it is finished with a high quality curing wood oil to seal the wood.

We tend to use a 1.8m long pine board to start with. We cut this in half to fit it on the machine, and then cut one complete flower press at a time - two in the 90cm long board - in two passes. So we make them up in batches of four at a time.

Next, we move onto printing. We allow the wood oil to cure at least overnight; but in practice we make the flower presses up ahead of time, so the wood oil generally has at least a week or so to cure. Printing is kind of the easy part! Our in-house UV printer can print directly onto the finished and cured wood, so this is just a matter of load and print!

The last component is the cardboard inserts. These are laser cut for convenience and the absolute accuracy this provides!

Finally, the flower press is assembled. The bolts are fitted into the base, the cardboard is placed onto the bolts, and the top is placed on. Then the washers and wingnuts are fitted and checked. It's then placed into a calico bag for packing and postage, and makes a great way to store or gift your flower press!

Since we've launched these, we've had people who've purchased them for grandchildren, and children who have purchased it for the their parents! It's a thoughtful and practical gift for Mother's Day, or for Grandparents to do with their grandchildren. Or even for yourself! We've been surprised by customers who've chosen them for all of the above reasons and more!

Select from our two designs, and let us know the name or names you'd like! We'll do the rest, and send you out a high quality flower press.

"Amazing quality product! Repeat customer who will always buy my cake toppers here as never fail to look special, arrive on time and wow my family and friends."